Engine damage caused by extending maintenance periods without monitoring

With a good oil it is easy to extend the period between oil changes, saving oil, filters and man-hours. The problems arise when this is done without monitoring the operation with oil analysis and having operators who are aware of the condition of their equipment.

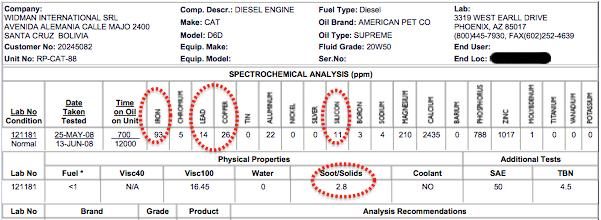

This D6 was operated 700 hours without changing the oil, although they did add some, since the end result is not 100% of the formulation they started with. The TBN is still better than some that are sold here as new. There is a slight problem with the air filter, allowing 11 ppm of dirt, but the main problem is the black smoke pouring out of the exhaust from bad combustion. This built up 2.8% soot in the oil, causing 93 ppm of iron wear, 14 ppm of lead from the bearings and 26 ppm of copper wear.