The effectiveness of a good maintenance plan

In these samples we can see the savings in wear and hours between oil changes created by improving the maintenance plan, buying better oils and filters.

These are four examples of agricultural tractors that operate in the worst dust conditions.

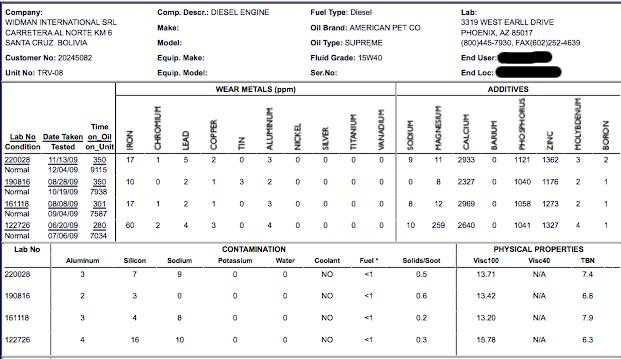

The first example covers more than 2000 hours of work. The first sample (at the bottom of the report) is a brazilian oil. It has 280 hours of work on it and 60 ppm of iron wear, with 16 ppm of dust. They changed the air filter, and the third sample has 350 hours with only 3 ppm of dust and 10 ppm of iron wear. This is a reduction of 21 ppm of iron from every 100 hours of use to 3 ppm per 100 hours, multiplying the engine life by 7 times.

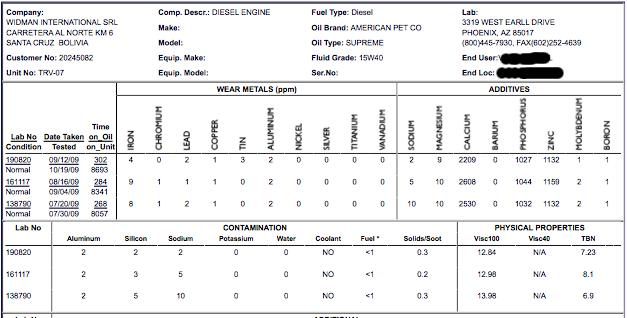

The next tractor had a mixture of the two oils in the first sample, and no problems with the air filter, since it only had 7 ppm of dust. But due to the oil quality it had 18 ppm of iron wear in 250 hours. The second sample shows they "cleaned" the air filter, raising the dirt level to 11 ppm. The iron wear was 15 ppm in 285 hours.

The real result shows up in the last sample (on top) where between the new air filter and the good oil, they only have 4 ppm of wear metals in 300 hours of use. In this period of 1800 hours, they were able to reduce the wear metals from 7.2 ppm per 100 hours to 1.3 ppm per 100 hours, increasing the engine life 6 times.

The real result shows up in the last sample (on top) where between the new air filter and the good oil, they only have 4 ppm of wear metals in 300 hours of use. In this period of 1800 hours, they were able to reduce the wear metals from 7.2 ppm per 100 hours to 1.3 ppm per 100 hours, increasing the engine life 6 times.

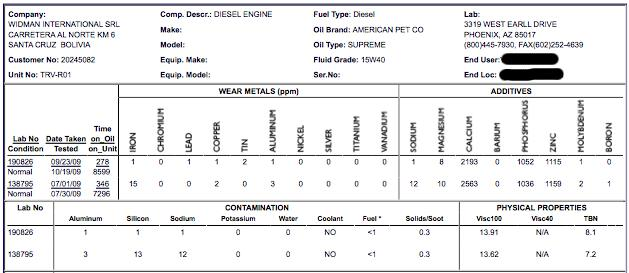

In the 1300 hours shown in these samples, starting with a slight mixture of oils in the first sample and showing 13 ppm of dirt passing through the air filter and 15 ppm of iron wear. After changing filters and oil brands, they were able to reduce the dirt contamination to 1 ppm and the iron wear to 1 ppm in 278 hours. This is a ten-fold increase in engine life.

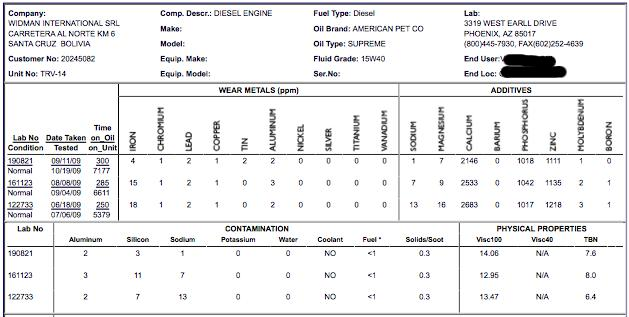

This tractor did not have any air filter problems in the period that we have analyzed. It started with 5 ppm of dirt and 8 ppm of iron wear. There are traces of the original oil throughout the 3 samples, but after teaching the operators not to "clean" the air filter they were able to reduce the contamination to 2 ppm in 302 hours with a resultant 4 ppm of iron wear. This cut the engine wear in half.