Viscosity shear

Oil breaks down or degrades with use. A lot of mechanics think they can measure the viscosity of an oil with their fingers to determine the quality or viscosity when it is used. Here we can see how the oil breaks down and can deceive us. There are 5 examples of how the Bolivian made Pennzoil looses its viscosity.

In the first example the oil has only been used for 160 hours in a relatively new engine. The viscosity is barely over the minimum for the 15W-40 grade.

Relatively new oil (only 160 hours)

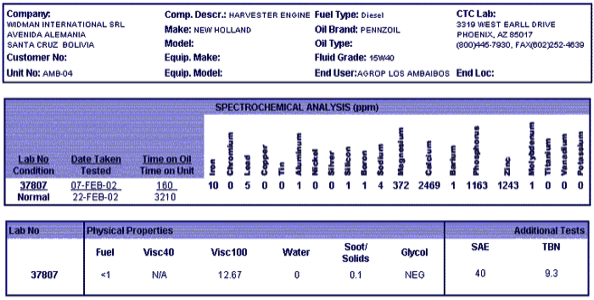

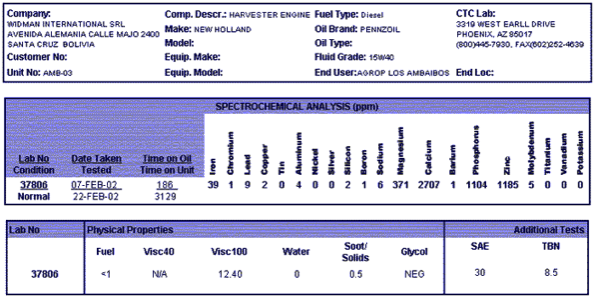

In the second example, we also have a relatively new oil, with only 186 hours of use. The viscosity has dropped down to 12.40 cSt, making it a 15W-30 oil and causing high wear of the bearings (lead) and cylinders.

Viscosity loss

Viscosity loss

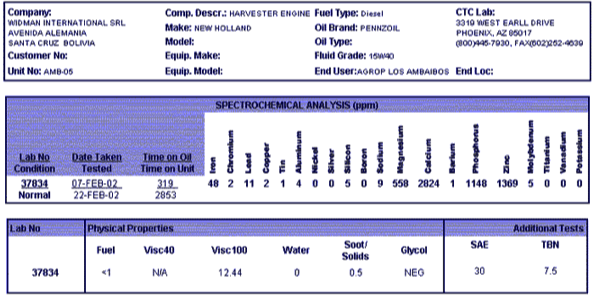

Here we have the same brand of oil where they have extended the service life to 319 hours because marketing said it was "long life". The viscosity is also below that of a 15W-40, and wear metals are very high, cutting the life of the engine.

Extending service life without having the necessary protection

Extending service life without having the necessary protection

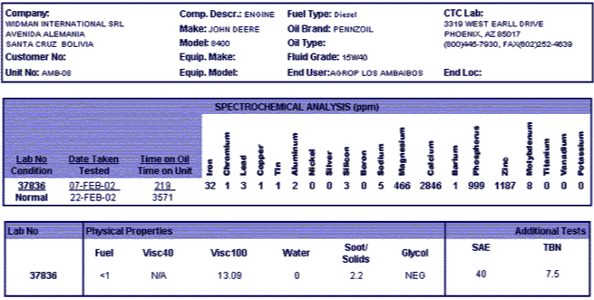

This fourth example shows how the finger-touch method of viscosity control is false. The oil only has 219 hours of use, but it has sheared down to a 15W-30 or less, then thickened up with 2.2% soot, making it seem to be in the right range. The 32 ppm of iron wear is excessive for this engine when there is no dirt ingression.

Tricking the viscosity test

Tricking the viscosity test

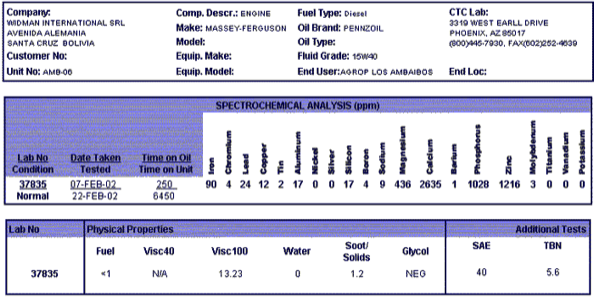

This sample also has high soot that has thickened an oil after loosing its viscosity. The combination of shear, soot, and dirt (17 ppm of silicon) caused 90 ppm of iron wear as well as a lot of lead and copper wear from the bearings.

Poor quality oil doesn't protect in adverse conditions

Poor quality oil doesn't protect in adverse conditions