Fuel in oil

An efficient fuel system is critical for the performance, efficiency and life of the engine. When unburned fuel enters the oil, it reduces the viscosity of the oil, eliminating or reducing the hydrodynamic lubrication of the bearings and other parts, wearing out the parts.

Here we see real examples of the wear caused by fuel entering the oil.

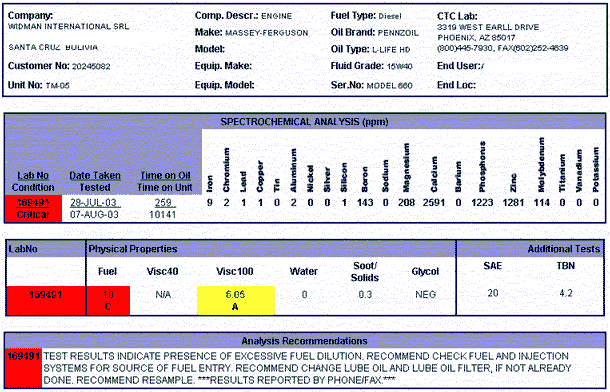

The first sample is from an agricultural tractor with an injector problem that allowed diesel to enter the oil in the last part of this oil cycle. Fortunately they noticed the diesel smell in the oil and stopped the tractor before additional damage was done. Analysis showed that the viscosity was reduced from 14 cSt to 6 cSt.

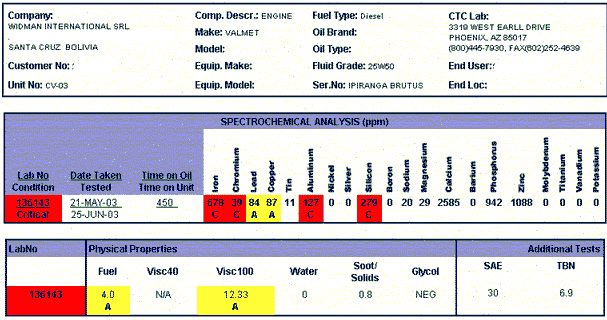

In the second sample we have less diesel, only thinning the oil to 12.33 cSt, but a serious problem with cleaning the air filter, causing 279 ppm of dirt to enter the engine. In reality it is likely that the oil was thinned more, but thickened by some of the dirt.

This oil was originally a 25W-50, with an initial viscosity over 16.3 cSt.

This wear is about 25 times the normal, basically cutting at least 20,000 hours off the engine life.

This oil was originally a 25W-50, with an initial viscosity over 16.3 cSt.

This wear is about 25 times the normal, basically cutting at least 20,000 hours off the engine life.

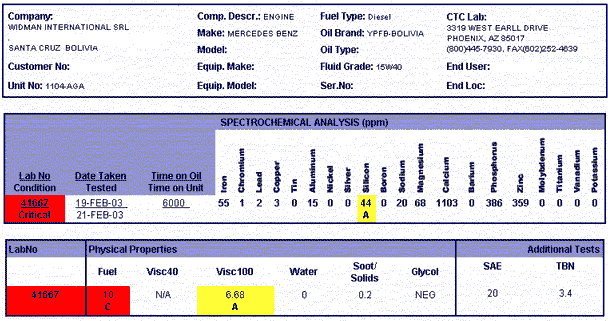

The final exmple shows an engine where the fuel and very high dirt contamination entered near the end of the oil change period, fortunately only causing 2 or 3 times the normal wear.

This sample also shows the use of an oil totally unsuitable for this engine, with only 1103 ppm of detergent, 386 ppm of phosphorous and 359 ppm of zinc.

This sample also shows the use of an oil totally unsuitable for this engine, with only 1103 ppm of detergent, 386 ppm of phosphorous and 359 ppm of zinc.